Accelerated life testing . is a valuable tool for determining or improving the quality of primarily electronic, electromechanical and mechanical systems and components.

Accelerated life testing is the process of testing a product by subjecting it to conditions such as stress, strain, temperatures etc. in excess of its normal service parameters in an effort to uncover faults and potential modes of failure in a short amount of time. It is the answer to the frequently asked question of “how long is a new design likely to work under normal use conditions?” or the question of “how can we improve the reliability of systems or components?”

There are basically two methods of performing accelerated life testing; the classic life testing (ALT) and Calibrated Accelerated Life Testing (CALT).

The presentation gives an overview of the methods for design and execution of accelerated testing with focus on applicability, advantages and disadvantages of the methods. Cases are included to exemplify the application of the methods.

ALT

Classic accelerated life testing based on acceleration models and acceleration factors are used to predict the “lifetime” for a given product in a predefined use environment.

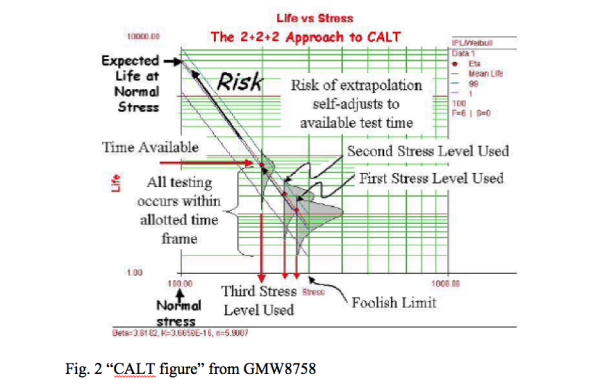

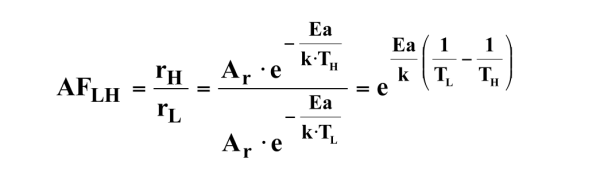

In an accelerated life test, the time-to-failure (tfH) for a given wear out failure mechanism is determined at high (accelerated) stress level (SH). Provided that the function G(S) applicable for the wear out failure mechanism under consideration and thus the acceleration factor (AFLH), is known, the time-to-failure (tfL) at a lower stress level (SL), normally the use stress level, can then be calculated as: tfL = AFLH · tfH.

The basic principle of accelerated testing is illustrated in the following figure.

Hence, the design of an ALT the following have to be considered:

- Define use and performance requirements

- Identification of relevant failure modes and mechanisms and thus acceleration models

- Determine extent of acceleration and test conditions

No single acceleration model can address all possible failure mechanisms of complex assemblies and products. Therefore, the challenge is to find the most relevant failure mechanisms to investigate. This may be done by failure mode analysis of the designed product associated with the intended use profile or by performing a HALT (Highly Accelerated Life Test).

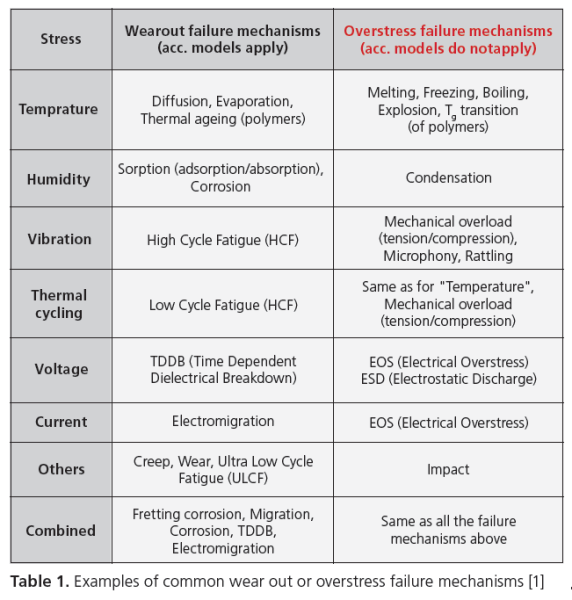

It should be noted that only wear out failure mechanisms can be addressed with accelerated life testing. Overstress failures are not time dependent in the way that is assumed in the acceleration models commonly used. Rather, they depend on the short term absolute stress level and should be addressed using relevant “overstress” test methods such as HALT. The table below shows examples of common wear out and overstress failure mechanisms.

Different acceleration models apply depending on the failure mechanism and thus the relevant stress i.e. the Arrhenius acceleration factor for temperature, the Inverse power law for vibration (high cycle fatigue), the Coffin-Manson acceleration factor another Inverse power law for thermal cycling (Low cycle fatigue) etc.

The extent of acceleration is limited by the risk that the stress acceleration may exceed physical properties of product materials and cause unforeseen damage by stimulating irrelevant failure mechanisms.

ALT performed on LED

The example below describes the tailoring of an ALT for a high power white light emitting diode (LED) which is used as light source in a food analyser.

The use and performance requirements for the LED are described as:

- Use temperature (laboratory) of the food analyser has been defined as 25 °C. At this temperature, the temperature inside the analyser is around 30 °C, which is used as the requirement for the LED.

- The food analyser is expected to be used 24 hours a day (worst-case).

- The performance requirement for the LED (i.e. the Performance limit) is >70 % of nominal light output at 350 mA drive current.

Identification of failure type and mechanism:

According to [1] “LEDs rarely fail catastrophically; instead, their light output slowly degrades over time”. This is typically caused by a combination of:

- Photo degradation of the LED die encapsulant (which is typically made from epoxy, urethane, silicone or a combination).

- Degradation of phosphors in the die encapsulant (the phosphor is typically used to make white light from a blue LED source).

- Degradation of the semiconducting element.

The information given above indicates that one or several temperature dependent wear out failures are dominating the lifetime of the LED. The underlying failure mechanisms are likely to be diffusion, thermal ageing or a combination. It is therefore expected that the Arrhenius acceleration model can be applied and the acceleration factor, AFLH calculated from the equation below:

Typical maximum operating temperatures for GaN based white LEDs are 80 °C to 100 °C. This limit is often stated just to ensure a reasonable lifetime and not because of possible overstress. Typical polymers used in LEDs have been tested at 100 °C and 140 °C. Thus, a test temperature between 80 °C and 100 °C seems to be on the safe side with respect to overstress.

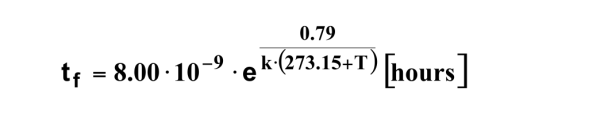

For an activation energy, Ea, of 0.79 eV and a “pre-exponential factor”, At, 8.00 ∙10-9 h, the test time at T = 80 °C is 1504 hours (~63 days) and 374 hours (~16 days) at T = 100 °C.

As the average time-to-failure tf (or “lifetime”) of the LEDs, as a function of temperature T [°C], can be described by:

CALT

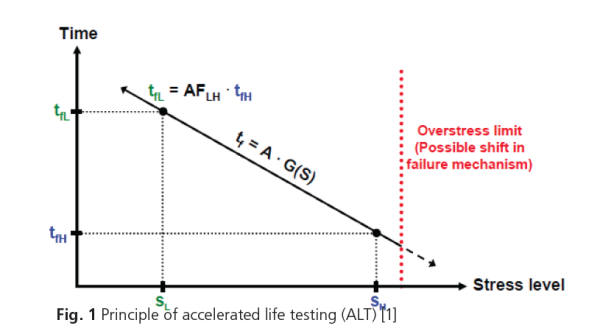

CALT (Calibrated Accelerated Life Testing) is a single stress analysis and test strategy used to find a product’s lifetime. The highest stress level is defined as slightly below the “Foolish stress level”, which is where the device instantly breaks down. A device is tested to failure at the highest possible stress level and the time to failure is recorded. The actual failure mode is identified. Test a new device to failure at a lower stress level, again record the time to failure. Perform an analysis of the results and test a third device at a stress level corresponding to the time available for reliability testing. Finally, the expected life at normal stress level is calculated based on all the test results. The figure below (taken from GMW8758) is illustrating this in a graphical way.

CALT performed on displays

The example below describes a CALT performed on three versions of displays – 6 samples of each (2 for each stress level). The purpose of the testing was to obtain a figure for the expected lifetime for the new version of the display by using the Calibrated Accelerated Life Testing (CALT) method

The CALT testing was performed as comparative testing, i.e. the new version of the display was directly compared with the older versions by using the same test exposures and test sequence for the three versions.

The detailed procedure was as follows:

Phase 1:

Establishing of the CALT test parameters (stressors) and test levels.

Relevant stressors were selected by analysis of earlier obtained field failures and the corresponding failure mechanisms. “Normal user” and “extreme user” for each relevant stressor were defined.

Phase 2:

CALT test # 1 with stressors close to “Foolish Limit” i.e. index 190.

Several stressors (stress parameters) were included in the testing in order to cover the relevant failure mechanisms i.e. extreme temperature cycling in combination with 6-axis broad-band random vibration. Thus, the CALT testing was performed as a so called Multiple Environment Over Stress Test (MEOST).

Foolish limit (index 200) was 140 ºC for the temperature span and 19.6 grms for the random vibration.

Phase 3:

CALT test # 2 with stressors lower than CALT test # 1 i.e. index 180, but with the same procedure as for CALT test # 1.

Phase 4:

CALT test # 3

The stressor level for CALT test # 3 was selected based on the results from test #1 and #2 and the time slot available for CALT test # 3. CALT test #3 was performed with 24/7 testing in order to obtain the longest possible exposure during the available time slot.

It is critical that a dedicated HALT is performed prior to the CALT in order to obtain “foolish level” and to avoid having to eliminate design weaknesses.

Based on the results of the CALT, a life-time of approximately 8 – 10 year was estimated for the new version. This was comparatively better than the two versions already on the market.

Susanne Otto

Reliability specialist

DELTA Test & Consultancy

References

[1] SPM-179 “Acceleration factors and accelerated life testing”

[2] SPM-180 “Reliable products – specification and validation of critical product parts”

[3] GM Test Procedure, GMW8758 “Calibrated Accelerated Life Testing (CALT)

[4] “Methods for product accelerated testing” (IEC 62506:2013)